As the world continues to grow and embrace the concept of alternative energy, many pioneering the industry still act as modern-day wildcatters with their crusade to develop clean energy sources and perfect their development and implementation. While battery power has stepped up to the proverbial plate as a viable form of power, others seek to improve upon its limitations, including life span, performance and development methodology.

Battery use knows minimal limitations. Batteries already claim responsibility for enabling portable computers, smartphones and the increasingly electric automobile. Since their power generation comes from lithium-ion batteries, the demand for lithium has increased in parallel to that for battery power. However, lithium battery power carries some baggage that consequently negates the spirit of clean and alternate energy.

Known as “white gold,” lithium is an alkali metal found in excessive quantities in certain countries. The mining process is plagued with safety concerns and can negatively impact the environment. To combat those factors, an associate professor from the mechanical engineering department of Louisiana State University (LSU) has used a grant to develop a replacement for the lithium battery. Associate Professor Ying Wang and her team of mechanical engineering students are working on a battery that is not only constructed of non-metal components but is also rechargeable.

“Lithium-ion batteries have good performance, but several serious issues,” says Wang. “It’s not sustainable and is very expensive, and the U.S. does not have deep reserves for lithium. Also, if you are extracting lithium from mines, you are using a tremendous amount of water, which has a severe impact on the environment.”

According to Wang, the concept of a non-metal battery is very new and consists of a molecular makeup that includes one part nitrogen and four parts hydrogen. This same configuration drives sustainability as nitrogen and hydrogen exist in the air. They are, therefore, abundant in nature. Because the composition of lithium-based batteries must be extracted from the earth, potential environmental destruction can occur, and there are limitations to the material supply.

Wang reasons that the non-metal makeup of her team’s design provides an additional benefit. The non-metal battery allows for using non-metal electrolytes inside the battery itself. While lithium batteries utilize flammable and toxic solvents, non-metal batteries use water-based electrolytes, which are increasingly safer to handle and manage.

“Lithium is not a stable metal, and the organic electrolyte in a lithium-ion battery could be flammable,” says Wang. “There has been a lithium battery explosion in the news. This is a recurring problem because when lithium batteries fail or overheat, they release flammable, toxic gases that can spark a fast-spreading fire. My group is designing an ammonium-ion battery that is much safer, lighter, more affordable, and can be biodegradable. It can also be thin and flexible so it can twist and bend.”

Wang admits that lithium-ion batteries offer a better performance rate than non-metal batteries, but counters that more research is still needed in developing these new battery designs. Her team’s ammonium-ion battery features an aqueous electrolyte with a high salt concentration. This is an active ingredient in lowering the freezing point, enabling use in sub-zero temperature settings.

By dissolving ammonium salt in water, the electrolyte can reject freezing. The amount of salt used will vary to achieve the desired freezing point. This also influences the ions’ conductivity and the battery’s electrochemical makeup.

With an enhanced need for safe and increased power and energy density capable batteries, Wang feels her LSU team has found the purpose and placement of its battery. Identifying those factors, Wang contacted NASA officials to evaluate the potential use of her team’s non-metal battery. The space program has typically considered lithium-ion batteries an energy source, but Wang indicates that increased safety issues have plagued their use. The LSU ammonium-ion battery stands as a prospective alternative in power generation.

“This study is expected not only to open a new direction of research on non-metal batteries, but will also enhance NASA research and technology while contributing to the overall research infrastructure, science and technology capabilities, diversity in higher education, and economic development of Louisiana,” says Wang.

If one considers the evolution of the automobile, changes in design can be witnessed frequently. Reasoning ranges from enhanced aerodynamics to simple boosts in aesthetics to surpass the competition. With every change in design, critical components needed to run and operate the vehicle must be strategically placed within the vehicle. The same can be said for boats and aircraft. The commonality exists in the potential need for non-metal batteries.

Wang indicates that without the metal structure, non-metal batteries allow their shape to be manipulated through exercises like bending to make fit and placement more efficient. This potentially decreases the time and money spent on specific designs that might be limited in supply. Instead, non-metal battery development offers the ability to meet needs through batteries developed through a sense of mass production. A battery that provides a “one size fits all” nature can meet customer needs while driving decreased production costs by eliminating the need for multiple shapes and sizes.

Decreased production times offer an additional caveat to non-metal battery development. These new batteries provide the chance to enhance clean energy through the final product put into production and the manner in which they are created and later discarded. Their development eliminates mining and the potential environmental hazards associated with mining, and the energy spent during creation sees a reduction.

Because non-metal batteries offer multiple scenarios of use because of their ability to be manipulated, size needs are reduced. One non-metal battery can alter its shape and fit various conditions of service. This reduces the need for high quantities of different shapes and sizes. This reduction allows less energy to be consumed during the production phase. By saving that energy, the carbon footprint benefits from the drop. Any energy saved instead of spent contributes to reducing emissions that influence the carbon footprint.

Non-metal batteries’ waste minimization factor enhances their stature as a clean energy source. While their current life cycle might not mirror lithium-ion batteries, they are biodegradable. At this juncture of research and development, their waste statistics contribute to their ability to serve as a clean energy source, even at the end of their life cycle. When they no longer have a use, they offer no harmful environmental side effects.

Through the results derived during development and production, non-metal batteries offer a viable place in the current world of alternative energy. Still, Wang says an even more pronounced stakehold will come through increased research. With the results and capabilities already identified, the future of non-metal batteries like LSU’s ammonium-ion subject should see endless opportunities as an effective component in helping solve the world’s energy crisis.

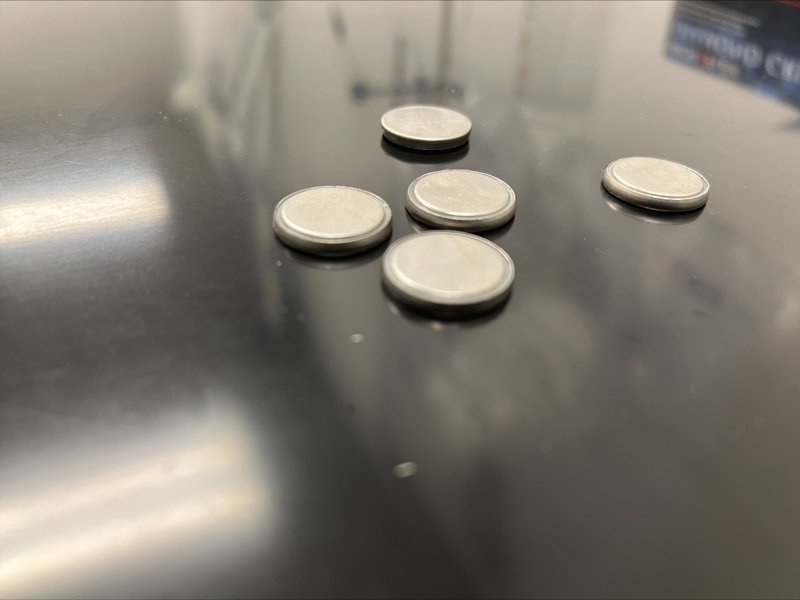

Headline photo: LSU engineering student, Shelton Kuchena, holding a cell used in the school’s non-metal battery prototype. Photos courtesy of LSU School of Engineering.

Nick Vaccaro is a freelance writer and photographer. In addition to providing technical writing services, he is an HSE consultant in the oil and gas industry with twelve years of experience. Vaccaro also contributes to SHALE Oil and Gas Business Magazine, American Oil and Gas Investor, Oil and Gas Investor, Energies Magazine and Louisiana Sportsman Magazine. He has a BA in photojournalism from Loyola University and resides in the New Orleans area. Vaccaro can be reached at 985-966-0957 or nav@vaccarogroupllc.com.

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.