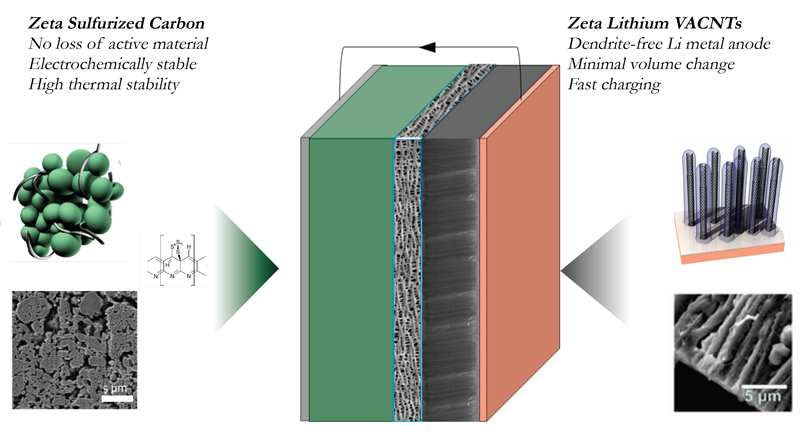

Zeta Energy is a Texas-based battery technology start-up that has developed a safe, low-cost, high performance, and sustainable battery built around a combination of two proprietary innovations: A sulfurized carbon cathode and a 3D structured metallic lithium anode. This combination yields a battery with a much higher energy density and lower cost than traditional lithium-ion batteries, while also offering comparable cyclability and better safety. The elimination of metals like cobalt, manganese and nickel also dramatically simplifies the supply chain for battery manufacturing. From the outset, Zeta developed its processes using industry standard equipment to enable its near seamless integration into existing gigafactories. Zeta also partnered with best-in-class equipment manufacturers to build trust, reliability and confidence with its partners and licensees.

Zeta Energy’s Founding

Zeta Energy’s Founding

Zeta Energy was founded in 2014 by Charles Maslin, an entrepreneur and investor with an avid interest in technology. Like many others, Maslin believed that the key to reducing environmental degradation and climate change was better batteries. Batteries that were lower cost, higher capacity and sustainably manufactured could enable more people to use solar power in their homes and could make electric vehicles competitive with vehicles that used fossil fuels.

Most analysts consider the largest market for rechargeable batteries to be electric vehicles, followed by grid storage (large-scale energy storage used within an electrical power grid). However, better, cheaper batteries also have the potential to expand the markets for consumer electronics, industrial equipment, medical equipment, aviation, aerospace, military and more.

Maslin thus knew that better battery technology could have enormous commercial potential. He began funding and licensing research being done on lithium metal batteries at Rice University. The group Maslin supported was led by world-renowned chemist and nanotechnologist Dr. James Tour, and was advancing the state of the art in carbon graphene nanotubes. Soon, Maslin had hired two of the group’s postdoctoral fellows, Abdul-Rahman Raji and Rodrigo Salvatierra, and founded the company Zeta Energy with the intention of producing and selling extremely advanced lithium metal batteries.

Maslin recalls, “There were urgent needs to be met… the need for the energy security and independence of a local, obtainable supply chain; the need for safer, higher performance batteries, the need for the capability of producing these batteries at a price point that would usher in rapid adoption of environmentally friendly alternative energy solutions. The urgent needs were clear, the inventors, brilliant, and the technology revolutionary. It did not take much vision to see the opportunity at hand, nor much convincing to attract a world class, seasoned, management team to bring that vision to fruition. That team includes our newly appointed CEO, Tom Pilette, our CCO, Michael Liedtke and our CFO, Michael Zemble – each of whom have been mission critical team members in both the formulation of our strategy and in its execution.”

The Technology

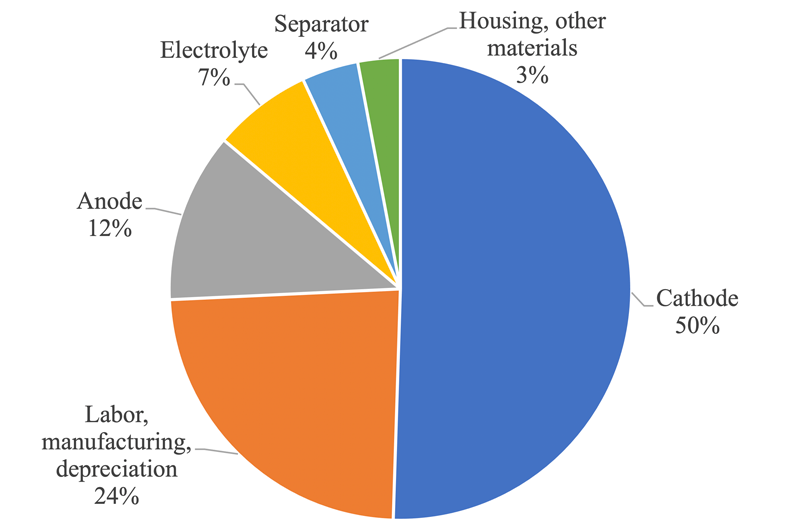

By the early 2020s, the lithium-ion technology that dominated rechargeable battery applications was clearly mature.1 The price per kilowatt hour had dropped close to 90 percent from its 2010 level of $1,191. However, further cost reductions were becoming unlikely as materials were now around 70 percent of the battery cost (see Figure 1). Materials costs can often increase rather than decrease as production volumes scale up.2

There was widespread consensus that a breakthrough innovation in battery technology would be necessary to significantly advance applications in these and other markets. By this time, it was also already well understood that lithium metal batteries – those that contained lithium in metal form instead of just lithium ions in an electrolyte – offered significant potential advantages in terms of how much energy a battery could hold for a given volume or weight. However, lithium metal batteries had not been widely commercialized because they suffered from some serious problems that needed to first be solved.3 One of the most significant of these is dendrites. In a lithium metal battery, dendrites (pointy projections of lithium particles) tend to form on the anode and can ultimately penetrate the separator between the anode and cathode, causing short circuits in the battery. Dendrites limited both the ability to recharge lithium metal batteries and created safety hazards.

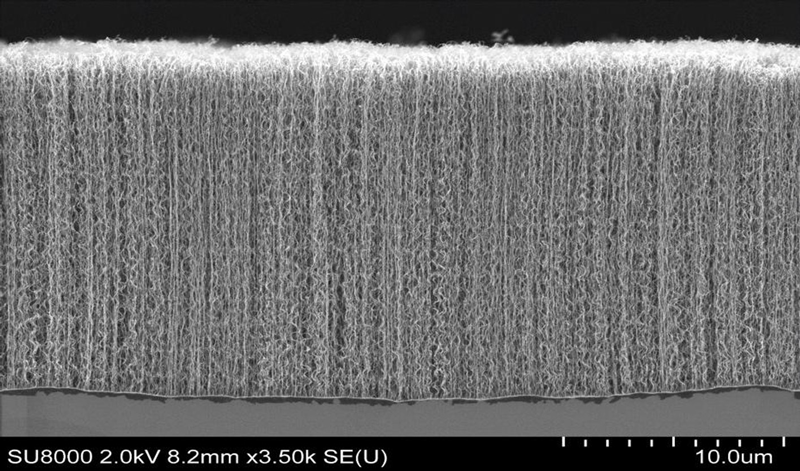

Zeta was able to solve these issues by creating a 3D structured lithium metal anode built on a carpet-like carbon nanotube (CNT) structure where billions of CNTs hold a tremendous amount of lithium while preventing the formation of dendrites (see Figure 2)4. This enables a lithium metal battery to simultaneously achieve both an extremely high energy density and have a low rate of degradation. The team also invented a roll-to-roll deposition method that enables CNTs to be grown directly in foil at high speed, ensuring that anode production would be scalable.

To realize the full potential of their anode, however, the team also needed a better cathode, leading to Zeta Energy’s second breakthrough: A sulfurized carbon cathode. Sulfur cathodes had been of considerable interest in the scientific community because sulfur is cheap and abundant and offers the theoretical potential of increasing the energy capacity of a battery up to 500 percent compared to conventional lithium-ion battery materials.5 However, several challenges to realizing this potential had limited their use. Namely, sulfur cathodes suffered from a polysulfide shuttle effect that resulted in “leakage” of active material, leading to degradation of the battery.6 Sulfur also expanded as it took on lithium ions, creating instability in the battery’s structure. As a result of these effects, lithium sulfur batteries had a history of poor “cyclability,” meaning that they could not be recharged very many times, making them commercially nonviable for most applications.7

After considerable experimentation, the Zeta Energy team created a breakthrough method of polymerizing sulfur that solves these problems. Zeta’s sulfurized cathode contains no elemental sulfur and yields no polysulfides. The cathode was tested by third-party laboratories that verified the cathodes could be cycled more than 300 times with negligible loss of performance.

As Chief Science Officer Rodrigo Salvatierra notes, “Sulfur cathodes have existed since the 1960s, but they didn’t perform well in applications that require many recharging cycles. We designed a special class of sulfurized carbon that enables us to use a high quantity of sulfur, is polysulfide free, and works across a broad range of electrolytes.”

Remarkably, Zeta’s process is also compatible with unrefined sulfur, saving the company even more money and energy compared to processes that use purified sulfur. Zeta holds numerous patents (and has many more pending) on both the carbon nanotube anode and the polymerized sulfur cathode (Figure 3).

The combination of a dendrite-free, high-density anode, and a sulfur cathode with excellent “cyclability” achieved what Forbes termed “The Holy Grail”8 in battery technology. As a bonus, Zeta’s battery does not use cobalt, nickel or manganese. Eliminating cobalt from the production of batteries is highly desirable since cobalt is primarily mined in the Democratic Republic of Congo, a country that is notorious for using child labor in cobalt mines.9

Winning Accolades

Zeta Energy’s achievements earned it a spot on the World Materials Forum’s “Top Ten Technologies” list in 2021, the “Coup de Couer Scale-Up Award” from World Materials Forum in 2022, and $4 million in funding from the U.S. Department of Energy ARPA-E’s EVs4ALL program in 2023. As of May 2023, Zeta Energy is scaling up its commercial production and validation center in Houston, Texas, and is in talks with several global automakers, leading aviation companies developing eVTOLs, and organizations developing grid storage capacity.

1 www.spglobal.com/marketintelligence/en/news-insights/latest-news-headlines/as-battery-costs-plummet lithium-ion-innovation-hits-limits-experts-say-58613238

2 Ibid.

3 batteryuniversity.com/learn/article/experimental_rechargeable_batteries

4 www.nature.com/articles/ncomms2234; https://pubs.acs.org/doi/abs/10.1021/acsnano; https://content.rolandberger.com/hubfs/07_presse/Roland%20Berger_The%20Lithium-Ion%20Battery%20Market%20and%20Supply%20Chain_2022_final.pdf

5 en.wikipedia.org/wiki/Lithium%E2%80%93sulfur_battery

6 www.electropages.com/blog/2020/01/why-lithium-sulphur-batteries-are-taking-so-long-be-usedcommercially

7 www.frontiersin.org/articles/10.3389/fenrg.2019.00123/full

8 www.forbes.com/sites/rrapier/2019/05/16/the-holy-grail-of-lithiumbatteries/#55f989243d63

9 www.ft.com/content/c6909812-9ce4-11e9-9c06-a4640c9feebb

Melissa A. Schilling is the Herzog Family Professor of Management at New York University Stern School of Business. Professor Schilling is a world-renowned expert in innovation strategy. Her research focuses on innovation and strategy in high technology industries such as smartphones, video games, pharmaceuticals, biotechnology, electric vehicles and renewable energies. Her research in innovation and strategy has earned numerous awards such as the National Science Foundation’s CAREER Award, the Best Paper in “Management Science and Organization Science” for 2007 Award, the 2022 Sumantra Ghoshal Award for Rigour and Relevance in the Study of Management, and the 2018 Leadership in Technology Management award at PICMET.

In addition to publishing in the leading academic journals, Schilling’s work has been featured in the Wall Street Journal, the Financial Times, Harvard Business Review, Bloomberg Business News, CNBC and more. Her textbook, Strategic Management of Technological Innovation(now in its 7th edition), is the number one innovation strategy text in the world. She is also the author of Quirky: The remarkable story of the traits, foibles and genius of breakthrough innovators who changed the world, and coauthor of Strategic Management: An integrated approach (now in its 14th edition).

Oil and gas operations are commonly found in remote locations far from company headquarters. Now, it's possible to monitor pump operations, collate and analyze seismic data, and track employees around the world from almost anywhere. Whether employees are in the office or in the field, the internet and related applications enable a greater multidirectional flow of information – and control – than ever before.